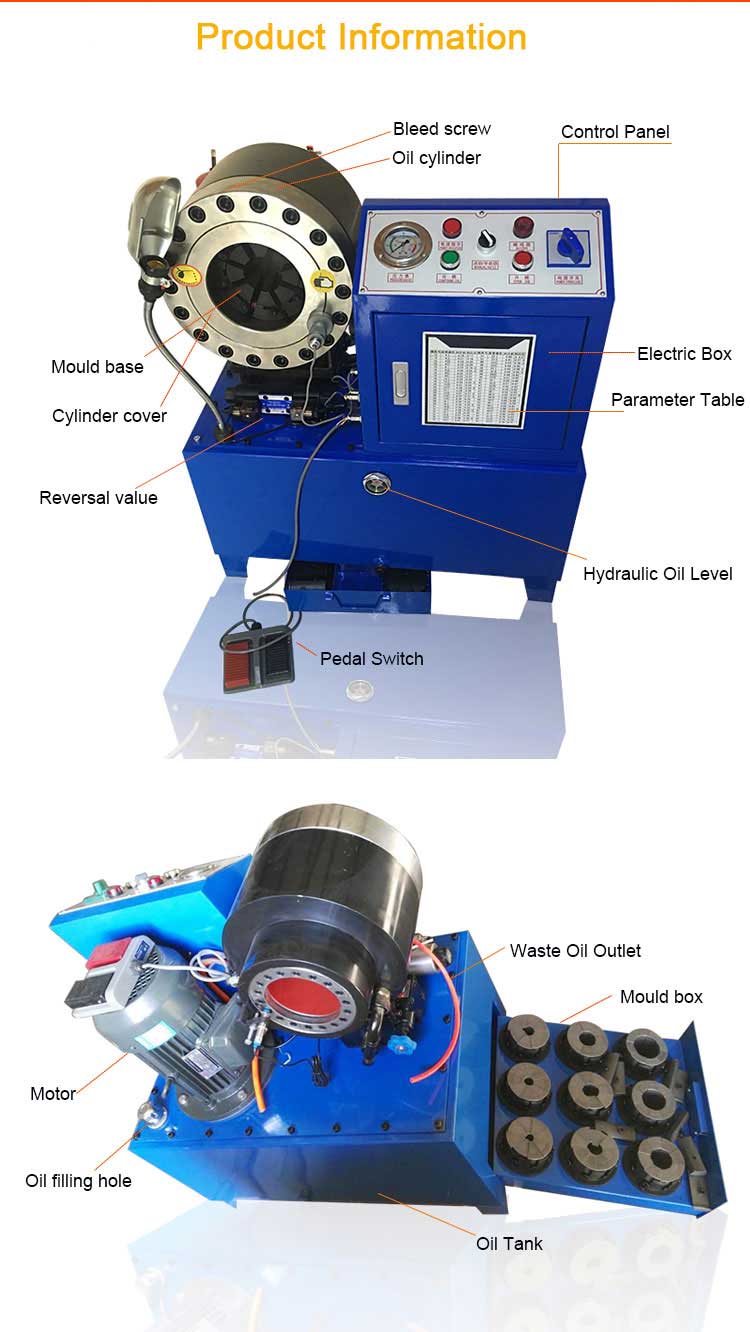

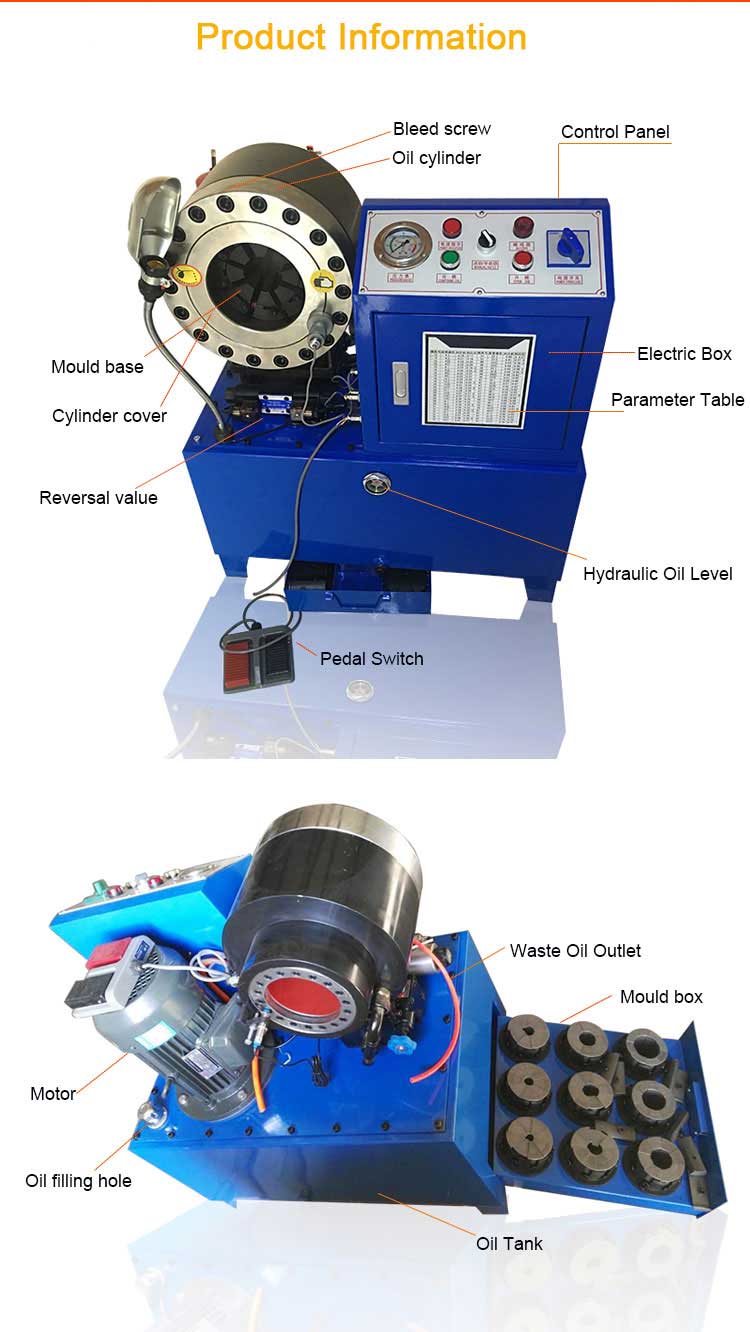

Installation and Operation

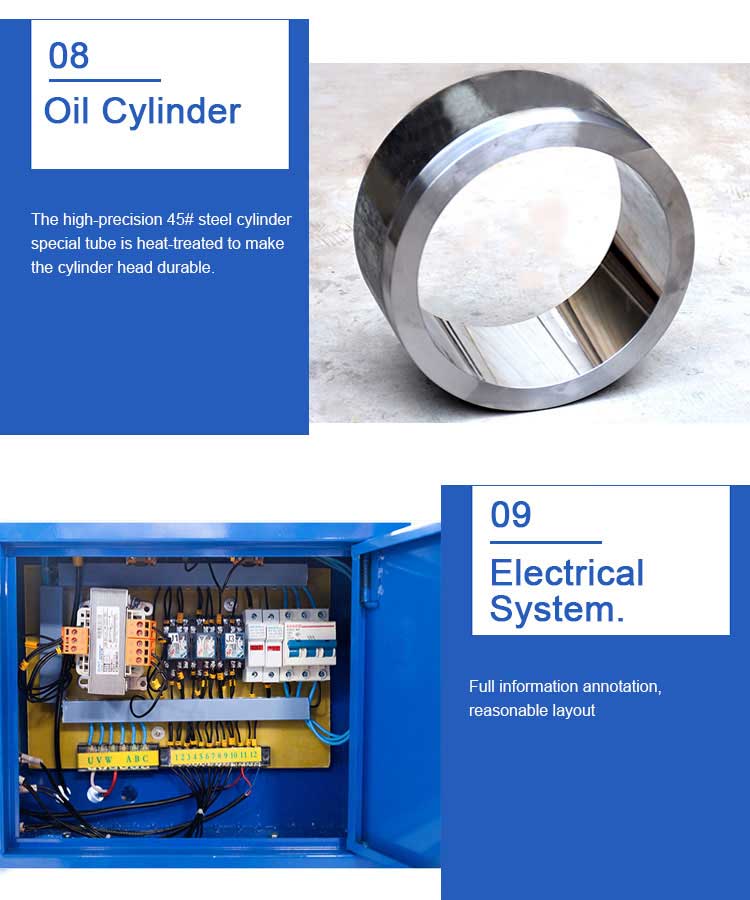

1.Add sufficiently 79 liters of Great Wall brand 46# anti-abrasion hydraulic oil. If the room tem- perature is lower than 10ºC, 10% transformer oil is need to add.

Connect the electric source well as per the machine requirements, to make the direction of the motor rotation to be consistent with the rotation direction marking, and grounding protection shall be done.

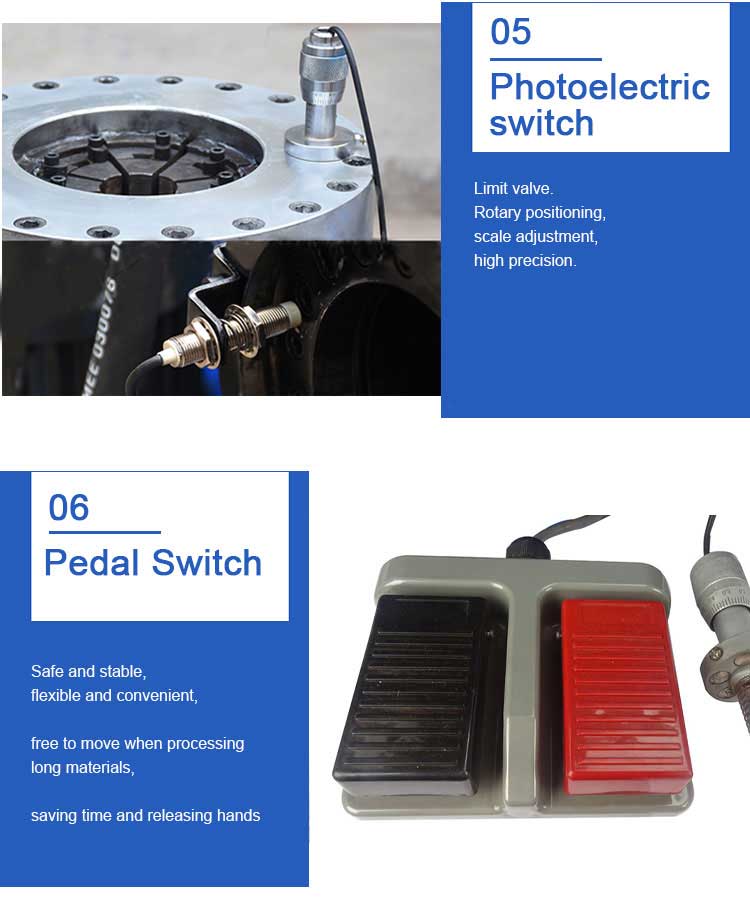

2.Regulating the scale

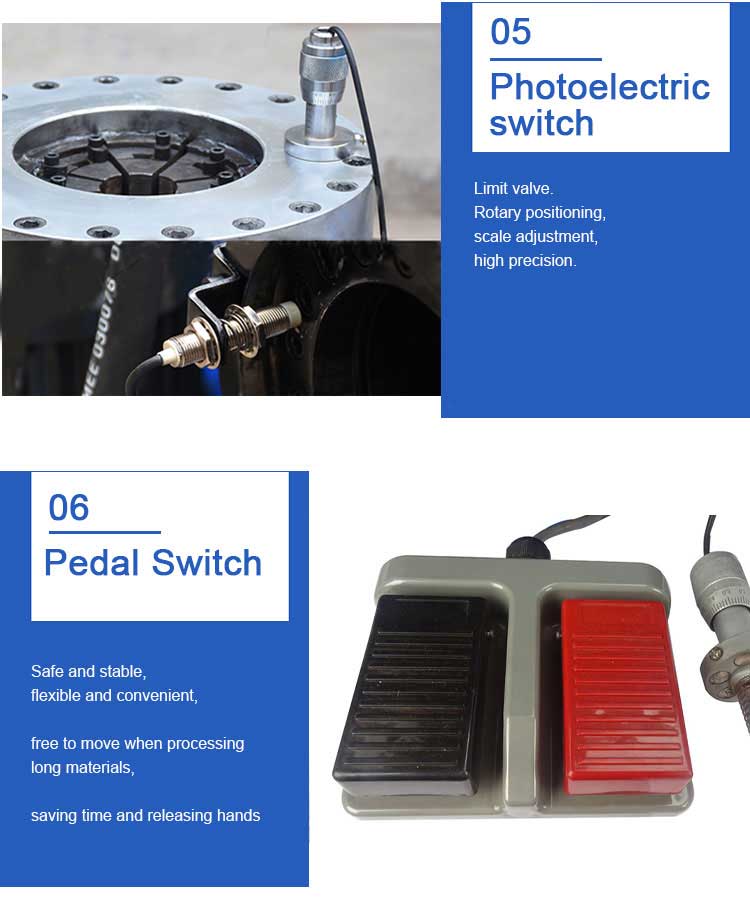

The scale is used for regulating the amount of the buckling. When it is regulated clockwise, the buckling amount will decrease, when it is regulated anticlockwise, the buckling amount will increase. The scale is connected together with oil cylinder end cover through three socket head screws and three springs on the scale base. When using a hand to pull the scale (vertical to the oil cylinder end cover direction), the scale can flexibly leave from the oil cylinder end cover. When releasing the scale, the scale will be recovered relying on spring force. Before the machine is turned on, inspect carefully if the scale telescoping is flexible and if the lead con- nection is reliable.

3.The primary scale is turned within 0 line of the secondary scale, turn the machine on for test run, and observe if all actions are normal. If when the piston conducts reciprocating move- ment, there is a crawling phenomenon, the bleed screw on the oil cylinder top shall be unscrewed for exhausting air.

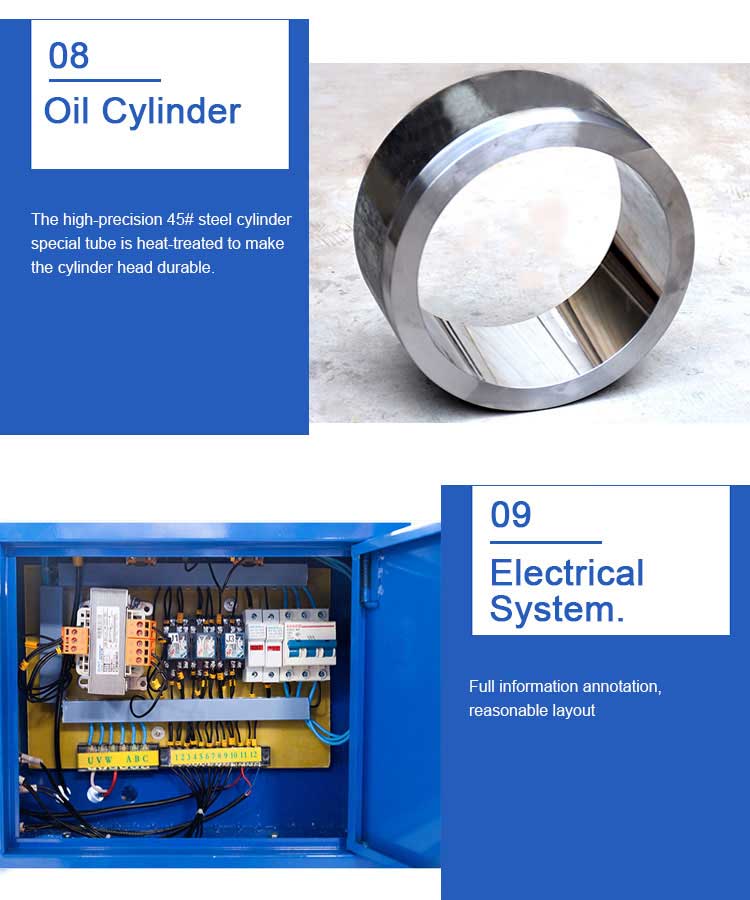

4.Pressure regulation

The buckling pressure and opening mould pressure will be regulated through two knobs at the back of the oil cylinder (see figure), when it is regulated clockwise, the pressure will increase, when it is regulated anticlockwise, the pressure will decrease (The pressure has already been well regulated when ex-factory).

5.Operation

Based on the size of the rubber hose to be buckled, select suitable mould as per the technical parameter reference table of the locking pipe and mount it on the mould base. Regulated well the scale position as per the data in the data in the table, the pipe locking can be done. After pipe locking, use a vernier caliper to mease the outside diameter dimension of the pipe sleeve after buckling to see if it meets the reference table data of the parameter. If it does not meet the data, the scale shall be precisely regulated until it meets the requirements. Because the manufactures of the pipe sleeve are different, so, specific dimension, material, hardness etc are certainly not the same. These factors would result different influences on the pipe locking result, therefore, the data in the table is only for reference, the detailed data take the pressure test as the basis.

Notices

1.When buckling, make the joint to locate the mould center as much as possible, the joint is not buckled on the hex nut.

2.Prevent tool and other foreign matter from entering the locking head.

3.After the work is finished for each time, the eight-block mould base must be made to extend to the greatest extent, this can make the spring to be at extension status. If not, the spring will be damage.

4.When working, the hand should not stretch into the locking head.

5.The power supply must be switched off when maintenance is done.

Maintenance and Care

Maintenance

The hydraulic oil in the oil tank should be frequently checked, if oil amount is found to be insuf- ficient, the oil shall be timely supplemented. If the oil liquid is polluted, it shall be filtered or replaced.

The locking head shall keep internal cleanliness. Avoid the foreign matters during processing to enter into the locking head oil cylinder via the mould to affect the normal use. Wipe out the foreign matters, which are brought by the mould body in time when buckling the joint.

Frequently fill suitable grease into the mould body for lubrication.

Promise

We will provide a guarantee to keep the machine in good repair within 12 months from the day when the machine is purchased. All fitting troubles will be free of charge repaired (or replaced if necessary) during the guarantee period. The damage resulted from improper use o accident damage does not belong to free of charge repair range.

The Packing List

1.The high pressure locking tube machine in model DX 68 one set

2.Mold (Total 10 Sets)Φ6 1 set

Φ10 1 set

Φ13 1 set

Φ16 1 set

Φ19 1 set

Φ22 1 set

Φ25 1 set

Φ32 1 set

Φ38 1set

Φ51 1set

FAQ

1. What level of service do you provide ?

*Your inquiry will be replied in 24 hours.

*Eight continuous years as an Alibaba Gold supplier and more than 25 years industrial technology and manufacturing experience .

* We offer free spare parts and service within 14 month warranty period.

* Technology Support by providing operation training videos .

* Professional after-sales service team.

* Give reasonable offers with the best quality.

2. What is our advantages?

* Competitive price: We can meet your budget and best-selling business very well.

* OEM Accepted: We can produce customized design.

* Good Service: We treat clients as friends and provide problem solving anytime you need.

* Good Quality: We have strict quality control system. Good reputation in the market.

* Fast & Delivery: We have big discount from forwarder (Long-term Contract).

* Door To Door Service.

3. Can you customize the machine for the customer?

Yes. We can, we also provide OEM for customers; If you need customized services, please contact us

4. What is the MOQ?

We usually provide 1 set for customers to test.